- Client Industries

- Aerospace

- Automobile

- Electronics

- Mechanical

- Medical and Dental instruments

- Military And Defence

- Hunting and Fishing

- Products Materals

- CNC Turned Parts

- Client Application

- Applications

Screw is the main type of fastener, typically made of metal, and indispensable mechanical industrial essentials in daily life as one of the most important Mechanical parts. It is widely used to fasten materials together and prevent pull-out, simply to say the main purpose of using screws is to make the industrial products into one piece.

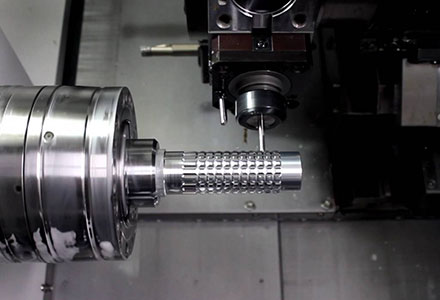

There are many types of screws for a variety of applications in Mechanical industry. Inferior screws can cause serious consequences, especially the machine screws for machinery industry. However mechanical screws are usually manufactured in large quantities, not hand-made artworks. Therefore in mass production, precision CNC turning technology guarantees the reliable quality and service life of the screws for safe using in machinery industry.

CNC Machining/Turning Screws For Mechanical Industry

Dajin Precision as one of the Top China CNC Machining Service suppliers in China, has been specialized in producing custom CNC Machining Screws (Rivets, Bolts, Nuts) for over 10 years with superior quality and custom service.

Our products of CNC Machined and Turned screw include Thumb Screw, Ball Screw, Screw Nuts, Bolts, Eyebolts, Rivet, steel screw, metal screw, brass screw, bronze screw and other types of CNC lathe machine screw. Reliable CNC Machined screws are supplied to consumers with high-precision and stable quality and popular prices.

Basic Specifications of our CNC Screw Machining Services

Dajin Precision has been a leader in the precise CNC turning service of OEM/ODM Mechanical Screws for the Mechanical industry. You can have the exact CNC screws you need for your mechanical equipment, fulfilling the precise compatibility requirements for a range of machinery, as we can produce such a wide array of custom CNC turned screws.

Advantages of Our CNC Machining Mechanical Screws

- Order custom CNC turning Screws not only means you get the highest quality it also means you get the best value.

- With decades of industry experience we are sure to offer input regarding design and construction for CNC machining screws to make the best cost-saving and time-saving production plan.

- Whether you provide us with anything from simple sketches, CAD drawings, or physical samples, we will work with you to customize and integrate a design that works for your product, pre-production free samples will be offered.

- Volume large or small, we can handle it all. We own our manufacturing facility so that we can keep all production in-house.

- From the design process to full scale production, our customers depend on a high-level of quality in the service and finished product.

- All CNC machining service for machinery parts - screws can be packaged or crated for safe, secure shipping anywhere in the world on time, one-stop service from inquiring, designing, producing to shipping.

Send us your inquiry to us, we will work off your design and with your people to manufacture CNC Lathe Screws to meet your exact demands and needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!