- Client Industries

- Aerospace

- Automobile

- Electronics

- Mechanical

- Medical and Dental instruments

- Military And Defence

- Hunting and Fishing

- Products Materals

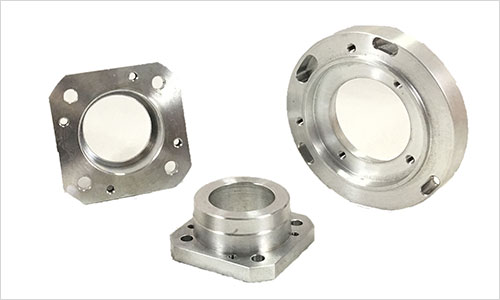

- CNC Turned Parts

- Client Application

- Applications

CNC Turning Services

Looking for professional OEM CNC turning services or want to receive a high-quality part from a reputable and reliable supplier? Dajin Precision provides excellent quality CNC lathe services United States and Europe based on the requirements to customers, featuring precision machined parts, lathe parts. Our precision CNC Turning Parts applications exist in a variety of industries including automobile, electronics, medical and more. We mainly serve customers from the United States, Europe, the Middle East, and more countries & regions.

Custom CNC Machining Services, Turning Components Manufacturing - What Is CNC Turning Service

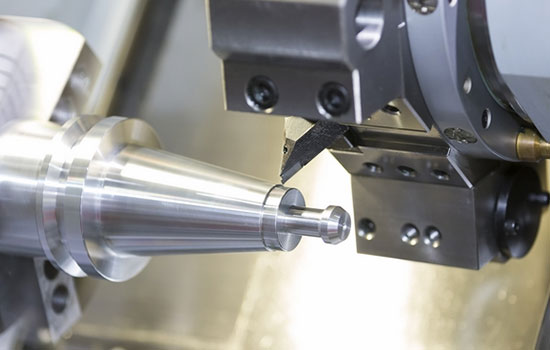

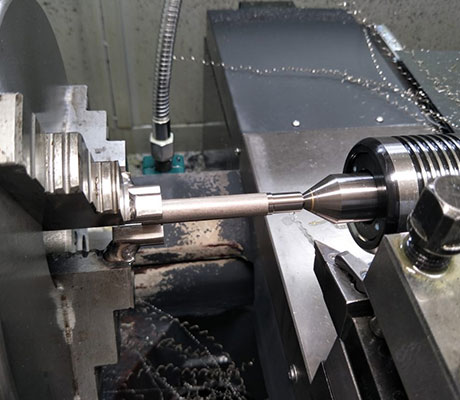

With the development of modern science and technology, more and more engineering materials with high strength and hardness are used. Traditional turning technology is not competent or able to process some high strength and hardness materials at all. CNC turning services make it possible and obtain obvious benefits in production.

CNC turning is a particular form of the precision machining process in which a cutter removes material by making contact with the spinning workpiece. That is, straight line or curve translation motion, not rotation.

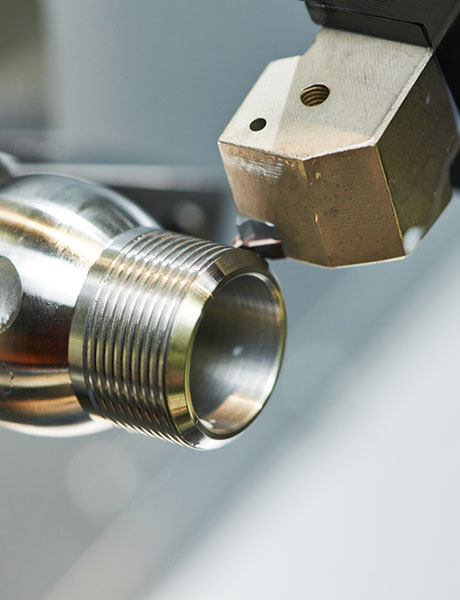

Suitable for processing round surface. Turning can be carried out on metals like aluminum, magnesium, steel, stainless steel, brass, copper, bronze, titanium and nickel alloy, as well as plastics like nylon, polycarbonate, through CNC Turning Lathe Services, which mainly used for processing axles, discs, sleeves and other workpieces with the rotary surface, is the most basic, widespread and important process method machine tool processing in machinery manufacturing and repair factories, which directly affects the efficiency, cost, energy consumption and environmental protection of production.

CNC Turning Services Manufacturer - Dajin Precision

Shenzhen Dajin Precision Hardware Co., Ltd is a 4-year Alibaba golden OEM CNC Lathe Services supplier, has been specialized in cheap turning services for the manufacture of precision CNC machined parts by high-quality production processes, ensure that our customers receive the highest quality standards.

Our CNC service equipment can be applied to a wide variety of products, ranging from simple bushings, spacers, and fittings to complex multi-sided components, In addition, our OEM turning services include online CNC service and lathe machining that is ideally suited for producing intricate parts where precision and accuracy are of the utmost importance.

Specifications of Our CNC Medical Tooling & Mold Parts

Application Industries and Main Product Contents of our CNC Turning Services

- Mechanical Parts Category: Fastener, Motor shaft, Empty metal cans, Conductive pins, Connector joint, Shaft sleeve, Pneumatic fitting, Hydraulic fitting, Hose joint pipe coupler, Screws(Rivet, Bolt, Nut), Eccentric(hollow) shaft

- Military & Defence industry: Airframe Parts, Consumables, Expendables, Avionics / Instruments, Engine Components, Rotables

- Medical and Dental Instruments: Production tooling components, Packaging accessories, Processing machinery replacement and spare parts, R&D fixtures, Testing parts, Analysis fitting

- Automobile Industry: Low pass filter shaft, Hydraulic valve, Valve housing, Sensor Housing, Pressure sensor housing, Temperature sensor housing, Pipe Joint, Throttle control shaft, Sensor metal shell

- Aerospace Industry: Fastener, Connector joint, Screw, Shaft, Eccentric hollow shaft, Pin

- Electronics Category: Metal Housing used for earphone, Aluminum pipe/tube used for tattoo and e-cigarette, Nozzle used for Shisha, Contact pins, Conductive Pins, Pivot pintle, Probes, Bushes, Test tooling

- Hunting & Fishing Industry: Blade ferrule, Insert, Insert Footer

- Other CNC Turning Application Industries

CNC Turning Features:

- High dimensional accuracy, high speed and high reliability

- Consistent quality

- Wide range of compatible materials

- Great productivity

- Low tool wear

Advantages Of CNC Turning Centers:

CNC turning/machining has many advantages over other machining processes.