- Client Industries

- Aerospace

- Automobile

- Electronics

- Mechanical

- Medical and Dental instruments

- Military And Defence

- Hunting and Fishing

- Products Materals

- CNC Turned Parts

- Client Application

- Applications

Joint Connectors, including the Joint Connector Nuts, Joint Connector Blots, Joint Connector Screws, are mechanical connectors which used to link between two structures, connect parts or components together similar to fasteners.

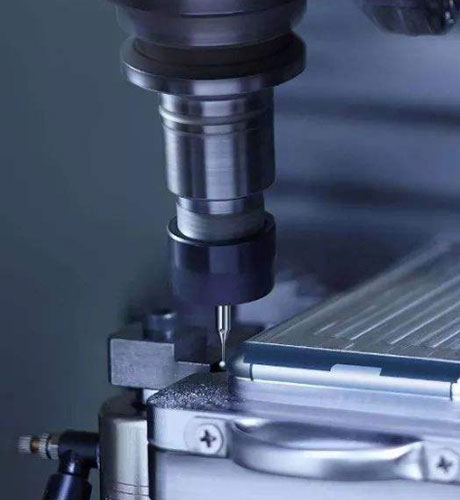

In Mechanical industry, the assembly of any equipment and machine is inseparable from the joint connecter parts, so connectors in different materials (brass, steel, aluminum, alloy, plastic and other metal) are mass-produced to meet different industrial needs. To meet the high quality, sturdy and precise production standards, CNC machining service for Joint Connectors are applied.

CNC Machining/Turning Engine Joint Connectors For Mechanical Industry

Looking for top-grade CNC Joint Connector Machining/Turning service from a reliable manufacturer? Then you are at the right place! Dajin Precision provides excellent customized precision CNC machined Joint Connectors. Specializing in CNC Machining Mechanical parts, with the ongoing improvement of technology, our CNC lathe Joint Connectors (CNC turning Connector Joints) are occupying a place in the China and Global market.

Incorporating the newest machining & milling processes with high standard techniques to satisfied both quantity & quality, our CNC machining solutions for Joint Connector Nuts, Joint Connector Blots, Joint Connector Screws are cost-effective and at the same time ensure the highest quality standards.

Basic Specifications of our CNC Machining Joint Connector

As one of the Top Supplier of CNC Turning service in China, Dajin Precision has the right advanced machines and technical team to manufacture your Joint Connector economically and to your precise specifications, covering OME production for nuts, blots, screws and other Joint Connector parts. Send us your design, draw, requirements now!

Advantages of Our CNC Machining Mechanical Screws

- Over 10 years experience in metal and plastic precision parts machining, professional and top grade CNC Machining Services for Machinery Joint Connector

- Advanced CNC machines and more than 200 experienced staffs provide highly skilled for manufacturing process

- Offer input regarding design and construction for CNC machined Joint Connectors to make the best cost-saving and time-saving production plan.

- All of our engineers and Q/C guys concern and active in every engineering and manufacturing stages by ISO standard, to make sure that only quality parts leave our plant

- Volume large or small, we can handle it all, as we own our manufacturing facility so that we can keep all production of Connector Joints in-house.

- From the design process to full scale production, our customers depend on a high-level of quality in the service and finished product.