What are UNF Threads and UNC Threads? | Difference Between UNF and UNC Thread

Threading is an important manufacturing technique for fasteners, there are many types of screw threads fabricated by CNC machining. Here we’ll introduce two typical threads with different pitch: UNF threads and UNC threads, what are the applications and difference between UNF and UNC Thread.

What are UNF Threads and UNC Threads?

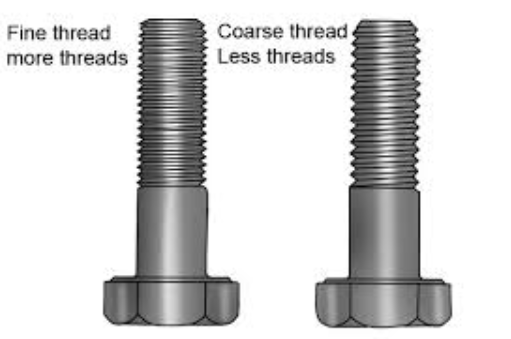

UNF and UNC are two symbols of Unified Screw Thread Series, which defined based on the amount of threads per inch and standardized with gauge. UNF threads are Unified fine pitch threads, while UNC threads are Unified coarse pitch threads. UNF and UNC thread screws are both used for fastening, but mainly applied in different fields. coarse thread has higher strength and find a thread is better for sealing. For detailed diameter, dimensions, you can search for the UNF and UNS thread chart with different measurement units.

Difference Between UNF and UNC Thread

When it is used as fasteners, the preloads of UNF and UNC threads are close. The effect of preventing loosing of fine thread is better than that of coarse thread. When it is used for adjustment, fine thread has more advantages. More difference between UNF thread and UNC Thread:

1)The UNF threads have smaller helix angle and better tightness, and it is more conducive to the self-locking of the thread. Therefore, it’s not that easy to be loosen compared with UNC threads. It is generally used for thin-walled parts and parts with higher anti vibration requirements.

2)The UNF threads have smaller pitch, there are more teeth are screwed in the same thread length, it can reduce fluid leakage, so it is used in the applications where sealing is needed.

3)The UNC thread has less teeth of the same length, larger cross-section size of each tooth, and more suitable for bearing larger tensile force and impact force.

4)Compared with fine screw thread, coarse screw thread has higher strength and good interchangeability.

5) UNC threading has also greater tolerances, better handles manufacturing and plating than UNF threading.

6)Due to the varying characteristics, Unified coarse screw thread and find screw thread have different uses.

Application of UNC (Unified coarse) thread

Coarse thread series (M/UNC/UNRC) is generally used for mass production of threaded fasteners, such as bolts, screws, nuts, etc. It has unique advantages in some rough operation applications that require quick assembly or disassembly and are easy to produce corrosion and damage.

Application of UNF(Unified fine) thread

The UNF thread has smaller pitch than the UNC thread with the same nominal specification, higher thread strength, smaller space occupation size and better self-locking performance. Fine thread series (MF/UNF/UNRF) is generally not used for large stress work, its general uses are applications need high fastener strength. It is mainly used for positioning, adjustment, fixation, etc. In addition, fine thread can be used for fine adjustment. For example, lens fixing of various optical instruments, micrometer and other instruments used for measuring, threaded connectors, battery cover of metal shell flashlight, etc. However, the height of the fine thread is small, so it is easy to get disordered when installing, and the burr has a great influence on the assembly, so it must be cleaned up. Additionally, the removal times of fine thread should not be too much.

Unified Screw Thread Chart Download

Want to get more detailed information about UNF and UNC threads? You can tell the types of screw threads and get to know the screw sizes, metric thread dimensions and thread specifications through the thread chart. Here you can check and download documentation of the Unified Screw Thread Series.