What is Cylindricity & Difference Between Circularity and Cylindricity | How to Measure Cylindricity | Dajin Precision

Cylindricity is important in the measurement of cylindrical machined parts, it’s a geometric tolerance that controls all the points on the entire surface of the cylindrical feature. Cylindricity tolerance can be applied to manage the manufacturing cost. Then how to measure cylindricity? Both are categorized as no datum feature and concerns circular elements, what’s the difference between circularity and cylindricity?

What is Cylindricity in GD&T?

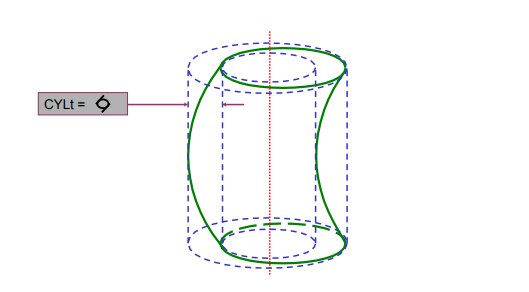

Cylindricity is classified into form category in GD&T standards, it indicates the similarity of an object and an ideal cylinder or how close the part conforms to the certain cylinder, it refers to the radial separation of two co-axial cylinders fitted to the total surface, requires the object to be straight enough along its axis and round enough to be consistent with the cylinder. The cylindricity symbol is as below.

Cylindricity is usually used for CNC turning parts must have good circularity and straightness, like bearings, shafts, dowel pins, bushes, etc., it’s a 3-dimensional control applied to the entire surface, limits the amount of cylindricity error allowed on the surface of a component, and is not relative to a datum. What is cylindricity tolerance? Two concentric (co-axial) cylinders along the full length of the feature, the distance between the inner and outer cylindrical tolerance, in which all points on the entire surface must fall into.

Why and How to Measure Cylindricity?

The form or shape of a cylindrical part will affect its use in machines, make the equipment out of normal use or fail to meet the original requirements, such as the roller. So the measurement of cylindricity is necessary to ensure the part is straight enough and round enough, and control the entire form.

The inspection and measurement of cylindricity

The measurement instrument for cylindricity you can use is a Roundness Measuring Instrument or a Coordinate Measuring Machine (CMM).

1. Put the object or cylinder part on a turntable of which the axis is conforming to that of the part, the nominal axis of considered feature should be aligned to precision spindle

2. Make the measuring instrument contact with the part surface

3.Rotate the object along the circle, and move the digital probe up and down, to scan the entire surface

The Difference Between Circularity and Cylindricity

Circularity refers to how close the cross-section of the workpiece to the theoretical circle. When the difference between the maximum radius and the minimum radius is 0, the circularity is 0.

1. Circularity is a 2-dimensional tolerance zone, which consists of 2 concentric circles whose radius spacing is equal to the tolerance value. Each circular element of the surface must be within the specified size tolerance, independent and perpendicular to the cylinder axis. Cylindricity is a 3-dimensional tolerance zone, which consists of two concentric cylinders whose radius spacing is equal to the tolerance value.

2. Cylindricity is a combination of circularity and surface straightness.

3. Circularity only measures the surface in one circle, while cylindricity also concerns how straight the cylinder is.