Instruments for Calibration of CNC Machine Tools - What Instruments are Used to Verify the Accuracy | Dajin Precision

The traditional methods of CNC machine calibrations need experienced operators and enough down-time, which causes a waste of time and cost. To ensure the product quality and verify the accuracy of machine tools, modern instruments for the calibration of CNC machine tools are widely used to avoid most of the errors, try to reach maximum efficiency.

What is CNC machine calibration and why calibrate the machine tool?

CNC machine calibration is to diagnose and correct errors after testing of the machine tool based on standard data for determining the accuracy, precision, repeatability. The continuous increase in production will influence tolerance, further affect the accuracy of CNC parts, so regular calibrations of CNC machine tools are necessary to avoid instrument deviation from its tolerance level and maintain the right working condition. You need to calibrate the machine tool in the following situations:

- CNC machine has been newly set

- CNC parts have out of tolerance

- CNC machine recently crashed or changed the workshop

Instruments for Calibrations of CNC Machine Tools - Instruments to Verify the Accuracy

In the process of fault detection of CNC machine tools. it's necessary and effective to use some special equipment, which can directly reflect the status of error from the perspective of quantitative analysis

1. Vibration measuring instrument

The vibration measuring instrument is the most commonly used and basic instrument in vibration detection, used to measure the running of the spindle, the motor and even the whole machine. It can amplify, transform, integrate and detect the weak signal of the vibration sensor, and directly display the vibration value of the tested equipment on the instrument or display screen. Different types of sensors can be selected according to the required parameters, vibration frequency and dynamic range, sensor installation conditions, etc. It is easy to operate and automatically indicates the status alarm, which is very suitable for the field equipment operation and maintenance personnel to monitor the equipment status, find problems in time, and ensure the normal and reliable operation. In order to meet the requirements of field test, the instrument is generally made into portable and pen type.

2. Infrared thermometer

Infrared temperature measurement is applying the principle of infrared radiation, convert the measurement of the surface temperature of the machining part into the measurement of the radiation power. The infrared detector and corresponding optical system are used to receive the invisible infrared radiation energy of the measured part, and transform it into other forms for display and recording.

According to the different response forms of infrared radiation, it can be divided into two categories: photoelectric detector and thermal detector. Infrared thermometer is used to detect the parts that are easy to heat in CNC machine tools, such as power module, wire contact, spindle bearing, etc. The instruments that use the infrared principle to measure temperature include infrared thermal television, optical scanning thermal detector and focal plane thermal imager. The infrared diagnosis are mainly through temperature judgment, similar comparison, file analysis, relative temperature difference and piggyback anomaly method.

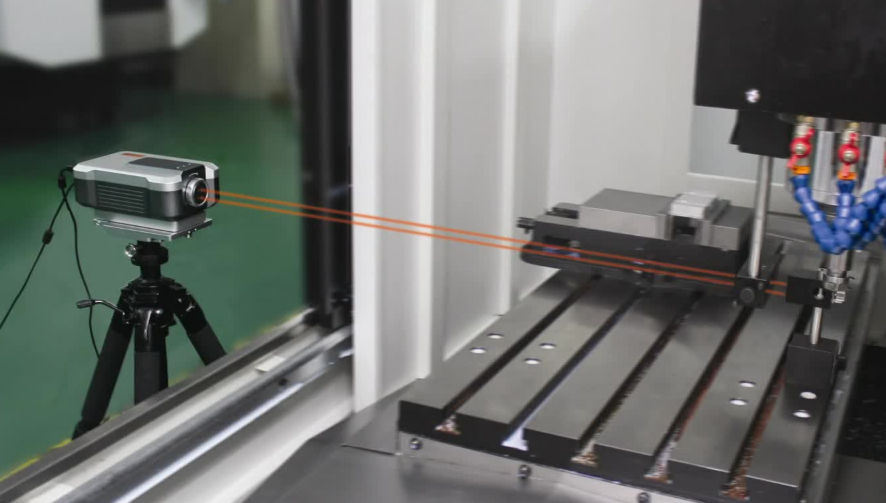

3. Accuracy measuring instrument

The laser interferometer is mainly used in the accuracy detection of CNC machine tools, it can calibrate the high accuracy (position and geometry) of machine tools and various positioning devices. It can complete the measurement of various parameters, such as linear position accuracy, repeated positioning accuracy, angle, straightness, perpendicularity, parallelism, and flatness, etc. In addition, it also has some selection functions, such as automatic pitch error compensation (applicable to most CNC Systems), measurement and evaluation of dynamic characteristics of machine tools, calibration of rotary coordinate indexing accuracy, trigger pulse input/output function, etc. Laser interferometer can be used in high accuracy, high efficiency, and convenient use. The measuring length can reach even tens of meters, and the accuracy can reach micron level.