What is Taper Turning - Different Methods of Taper Turning on CNC Lathe Machine | Dajin Precision

Other than cylindrical parts, CNC taper turning or conical parts are also widely used and it is easy to assemble and disassemble. Are you searching for how to do taper turning? In this guide, dajinprecision.com introduces 4 different methods of taper turning on lathe machines.

What is Taper Turning?

Taper turning is a manufacturing method used to produce tapered turning parts, which has uniformly changing diameter from one end to another. So the taper turning refers to a process of gradual reduction in outer or inner diameter from one end to the other of the cylindrical workpiece or material block. Taper turning is usually performed on a lathe machine.

Different Methods of Taper Turning on Lathe - How to Do Taper Turning in CNC Lathe Machine?

Taper turning in lathe is possible when the axis of rotation of the workpiece and feed direction are at an angle. Here are some effective methods of taper turning on CNC lathe.

1. Tailstock setover method

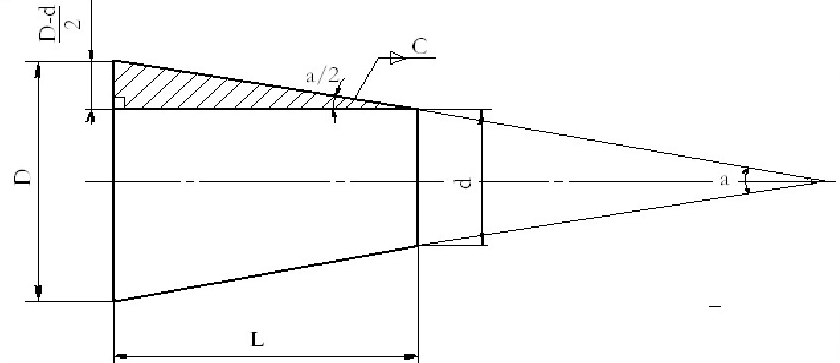

This method is ideal for small taper angle. The workpiece will be placed betwen the live center and live center, the taper can be turned between centers only. The tailstock is clamped over the lathe bed opposite to the headstock. In normal position, the dead center will lie in the rotary axis, then the movement of tailstock can be realized by the setover screw. When the workpiece is fixed using the live center and dead center, its axis of rotation changes to the line that’s at an angle with the feed. When the feed is given to the tool, its cut at an angle to the axis of workpiece produces a taper. You can calculate the setover length with the formula: S=L*(D-d)/2l, l: taper length, L: total job length, d: smaller diameter, D: larger diameter. This method is best for creating long tapers where power feed can be used. Good surface finish can be obtained for your taper turning part as well. Please note that the set-over amount is limited, then the taper angle is limited to about 8 degrees.

2. Use compound slide

It’s suitable for cutting short tapers with high taper angle, which refers to short, steep taper. The workpiece held in the chuck and rotating around the lathe axis, rotate the composite rest to the desired angle and clamp it in place.

3. Form tool method

One of the simplest way to fabricate short tapered parts, secure the tool to required angle, feed the tool perpendicular to the lathe axis when the workpiece is rotating. The tool cutting edge must be longer than the taper. This method often used under large force in slow speed.

4. Use taper turning attachment

The taper turning attachment consists of a bracket or frame attached to the rear end of CNC lathe bed, to support the guide plate or bar pivoted as its center. The guide bar can swing and be set in any required angle. How to use the taper turning attachment? First remove the binder screw to make the cross slide away from the lead screw, then screw down the rear end of the cross sliding block and the guide block with bolts. When the longitudinal feed is engaged, the tool mounted on the slide will move along the angular path.