What is CNC Fixture - Fixture Types, Functions, & CNC Lathe Workholding Methods | Dajin Precision

In the mechanical manufacturing, a number of fixtures are used to complete the required processing, assembly and inspection. It’s an important CNC tool that can improve productivity and ensure the machining accuracy. What is a CNC fixture and what types of fixtures are there? Other than that, let’s find out the effective CNC lathe workholding methods.

What is a CNC Fixture?

CNC fixture, also called jig, is a kind of device used to clamp workpiece and guide cutting tool on CNC machine tool. CNC fixture can adapt to the high precision, high efficiency, multi-directional processing simultaneously, digital program control and single piece small batch production of computer numerical control machine tools. Lathe fixture is to secure the workpiece on the machine through holding in the chuck jaws or fixing to a face plate, and can clamp it quickly and reliably to get into machining or testing, ensure the machining accuracy of CNC parts. The components of a lathe fixture usually including a base, location and clamping devices.

What is Lathe Fixture Used for?

The main function of the fixture is for Workholding (from location to clamping).

- Positioning: make the workpiece fixed on the correct machining position relative to the cutter and machine tool, and ensure that the machined surface meets the requirements.

- Clamping: after the material block is positioned, the force is applied to the workpiece by the clamping device, and the part is fixed and clamped firmly, so as to maintain the correct position during the processing.

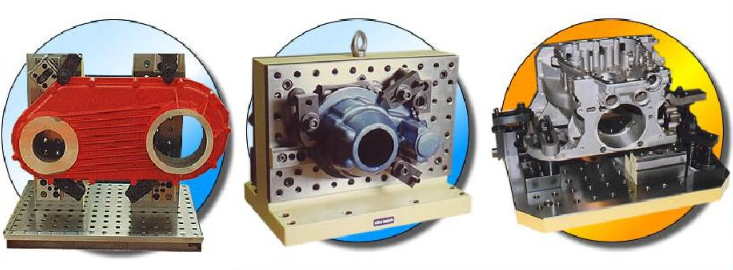

Types of CNC Fixtures or Jigs

1.Based on the applicable machines, the CNC fixtures can be divided into:

Turning fixtures

Milling fixtures

Drilling fixtures

Boring fixtures

Grinding fixtures

2.According to the uses, the CNC fixtures can be classified as:

Universal fixture

Special fixture

Adjustable fixture

Modular fixture

Combination fixture

3.Classify CNC fixtures by power source

Manual fixture

Pneumatic fixture

Hydraulic fixture

Electric fixture

Magnetic fixture

Vacuum fixture

CNC Lathe Workholding Methods - CNC Workholding Solutions

There are several ways for holding workpiece on the CNC turning lathe.

- Chucks: extensively used for holding CNC parts of various shapes (round, square, hexagonal, and irregular) in machining operations, most commonly applied lathe chucks are three-jaw universal, four-jaw independent and collect chuck.

- Face plate: basic lathe workholding accessory, a circular metal plate to be fixed to the end of the lathe spindle, then clamp the CNC lathe parts, generally use T-nuts in slots or threaded holes in the faceplate. This CNC workholding solution is suitable for large part that can’t be held in a chuck or between centers.

- Mandrel: clamp the internal machined workpiece between centers for further machining operation that concentric with bore, the mandrel types including plain mandrel, expanding mandrel, gang mandrel, stub mandrel.